A $798-million Dallas highway project improved traffic flow into and out of the city's downtown. The new "Horseshoe" interchange corrected the traffic bottlenecks and safety concerns of the original design from the 1960s with improved geometery, wider bridges, and relocated exits. Raba Kistner performed independent quality assurance services for the Dallas Horseshoe Project, including design quality assurance review, construction quality acceptance of all the work elements including inspection and material testing, and auditing of construction and design processes.

This article was reprinted from the May 2018 issue of Civil Engineering.

By Robert M. Brown, P.E., M.ASCE

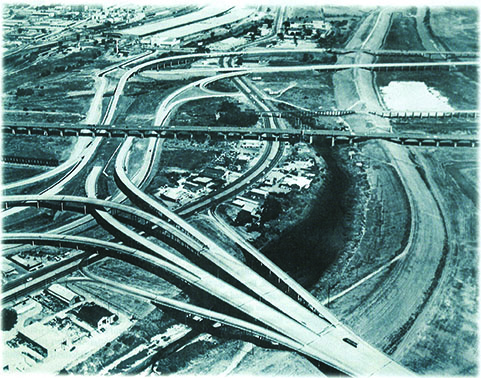

Growing up in Dallas in the 1960s, I often rode with my parents through an amazing downtown highway interchange known as the Mixmaster. I marveled at its pristine, space-age design as we navigated its intricate maze of on ramps and left-turn exits that connected Interstate 30 and Interstate 35 East and crossed Dallas's Trinity River. Gradually, though, the luster of this once magnificent interchange faded. What was state of the art when it opened in the 1960s eventually developed an unfortunate reputation as a site of frustrating bottlenecks, lengthy traffic delays, and safety concerns.

The original intersection was deteriorating and ill-equipped to handle the estimated 450,000 to 500,000 vehicles that passed through it on a normal weekday. The bridges that crossed the Trinity River has inadequate capacity, narrow lanes, and large sections of deteriorating structural components that frequently required emergency repairs. The unavoidable truth was that the Mixmaster of the 1960s, which accommodated roughly one-tenth of today's traffic volume, was in desperate need of more than just upgrades. It begged for a wholesale replacement.

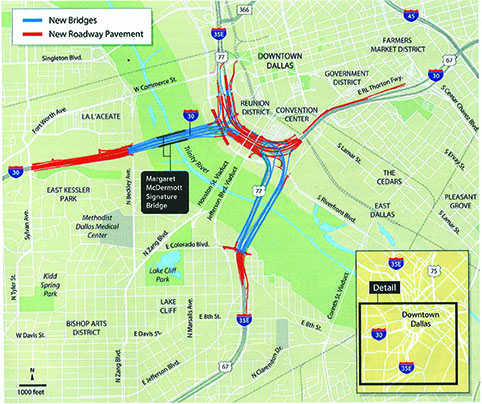

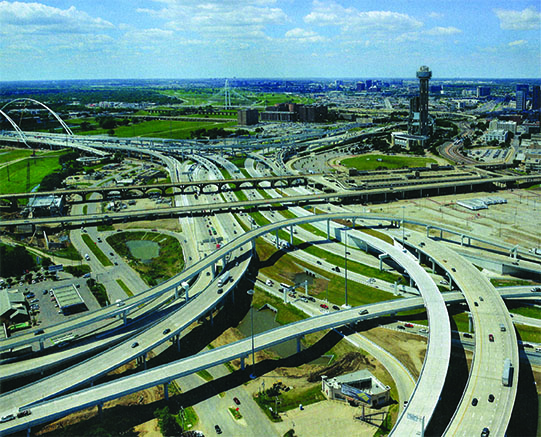

Today the Mixmaster is a distant memory. It has been completely replaced by the Dallas Horseshoe, a $798-million interchange that has substantially improved the flow of traffic crossing the Trinity River along I-30 and I-35 East to get into or out of downtown Dallas.

Pegasus Link Constructors (PLC)--a joint venture of Fluor Corporation, of Irving, Texas, and London-based Balfour Beatty--had been awarded the design/build contract to deliver the Dallas Horseshoe on behalf of the Texas Department of Transportation (TxDOT). As lead designer to PLC, New York City-based WSP USA was responsible for designing the roadways, bridges, river crossings, retaining walls, drainage, geotechnical engineering, and maintenance of traffic plan. In my role as Dallas area manager, I led the bidding phase and served as principle-in-charge during the design phase.

Design of the Horseshoe began in 2013, and construction commence in January 2014. The project was substantially completed on schedule in April 2017.

One of the greatest problems with the Mixmaster involved its confusing left-lane exists. Motorists are conditioned to bear right when preparing to exit a highway, so left-lane exists on the Mixmaster felt unnatural, especially for drivers unfamiliar with this arrangement. As a result, the Mixmaster was notorious for its alarming frequency of overturned tractor trailers. No matter how many warnings were posted--or how many communication methods were attempted--trucks would flip on their sides after drivers realized too late that they were in the wrong lane and unsuccessfully weaved to the left, losing control of their vehicles and spilling over the roadway. These crashes would create traffic chaos for as much as 12 hours while crews cleared the highway, not to mention the potential danger to life and limb.

To further complicate matters, as the predominately north-south I-35 approaches the Dallas-Fort Worth region, it splits as I-35 East goes through downtown Dallas and I-35 West goes through downtown Fort Worth. Traffic making its way between a southbound section of I-35 East and a westbound section of I-30 had to merge along Riverfront blvd before completing that transition. For anyone unfamiliar with the complicated alignment--and even those of us who were all too familiar with it--the Mixmaster could be a nightmare.

Naturally, correcting the odd geometry of the Mixmaster became one of our highest design priorities. The plan we developed for the Dallas Horseshoe eliminated all left exits, providing direct connections from northbound I-35 East to westbound I-30, and eastbound I-30 to southbound I-35 East. Under the new design, the different lanes of traffic no longer merge, and both I-30 and I-35 East have their own parallel freeway segments. Additionally, I-30 at the Trinity River was expanded from 6 lanes to 17, while I-35 East at the river increased from 9 to 18 lanes. As a result, today there is much less weaving, less congestion, and the roadway is much safer for motorists.

Dallas Horseshoe Improvements

TxDOT required that traffic continue to flow through the interchange at all times throughout construction--without using detours that would clog secondary roads. That meant that we were not only removing and replacing every square inch of road, every bridge, and every wall, but doing it while we kept traffic moving and motorists safe.

The design/build contract incorporated several incentives, including a lane rental specification. It meant that if at any point we made the decision to close freeway lanes, we had to pay TxDOT for the right to do so. The longer we closed the lanes, the more we had to pay, and if we closed lanes during daytime or peak traffic hours, we had to pay even more. Clearly that meant that it was in everyone's best interests to keep lane closures to a minimum. Considering that the Dallas Horseshoe included the construction of more than 73 lane miles of new roadway, 37 conventional bridges and more than 60 retaining walls, this was no small task.

One way we met the challenge was by building the new roadways from the outside lanes inward. This allowed motorists to continue using the old lanes until the new ones were completely ready for traffic. The traffic then transitioned to the outer lanes so that work on the inside lanes could begin.

Another challenge with the Mixmaster was the fact that the interchange also passed underneath the Houston Street Viaduct, a repeating concrete arch structure and historic landmark build in 1911 and added to the National Park Services' National Register of Historic Places in 1984. All lanes, ramps, and roads had to pass over or under this bridge with no impact. As construction progressed, WSP and PLC developed more than 70 geographic refinements to the plan, such as shifting phased construction out of the way of existing traffic. The team also kept lane closures to a minimum and worked to lower costs for the contractor.

WSP's geotechnical engineering responsibilities for the project included pavement design; bridge foundation design consisted of of reinforced-concrete drilled shafts; and ground improvement and global stability analysisfor the retaining walls. Special shoring was also required in constrained areas. The entire storm drain system was also removed and replaced because of increased runoff from development and to achieve the client's desired design criteria.

Retaining walls were installed throughout the Horseshoe work site, but locations were often limited by the constrained right-of-way within the construction area. The project used mechanically stabilized earth retaining walls, which were typically 5 to 25 ft in height. The mechanically stabilized earth wall foundations used a leveling pad along with granular backfill and reinforcing grids to complete the design.

The Horseshoe was constructed on some of the most challenging soil and rock conditions in North Texas. The site featured largely alluvial soil deposits by the Trinity River, not high in strength or stability. Rather than rely on empirical data and standard charts and graphs, the geotechnical team performed full-scale load testing to develop the foundation design. This work included test shafts with load cell devices and a full array of displacement, and stress monitoring devices to develop site-specific load-displacement curves. The geotechnical team used these curves to optimize bridge and wall foundations, which promoted greater overall project economy and value.

I'm often asked Horseshoe got its name. The origin is quite simple: it refers to the U shape of the project, which resembles a horseshoe in plan. Indeed, the concept of "simple" is a recurring theme for this project. Over goal was to simplify travel for motorists. However, to reach that point required complex planning and constant coordinator between the designers and the builders. It's not always easy to make things easy.

With such a large scope of work and an aggressive schedule, efficient communication was essential to the success of the Horseshoe project. To facilitate open communication and expedited decisions, a technical working group leader was appointed from the design team, construction team, and TxDOT; there was one for each discipline. These leaders were experienced and able to make critical decisions that were instrumental in maintaining the aggressive design schedule.

We were constantly assessing the progress of the project and providing ideas to improve traffic flow while keeping construction on crack. One example was our use of "active traffic management" techniques. For more than 50 years, traffic on the Mixmaster exited to the left. But midway through construction, motorists familiar with the way things had been done on the Mixmaster suddenly had to be retrained to find their exits on the right. After the lanes began to take shape, it was determined that we needed this message about the new exit design to stand out so that drivers would take notice. The answer was the installation of eight bright, eye-catching digital lane-use signs over each lane, which helped drivers easily identify the correct lane to take to reach the new exit locations. It proved an effective solution to the problem.

At other times, an idea that had not worked early in the design process suddenly became more viable as the project progressed. This came into play while accommodating TxDOT' s technical requirement to keep the ramps and other access points open throughout construction. Early in the design process, we had been convinced that the use of temporary detour pavement and even temporary bridges would be necessary to maintain these movements. But by having the design and construction teams work together, a phasing plan was created and plotted to eliminate all temporary bridges and reduce detour pavement requirements.

Cooperation during the bidding phase in modifying the roadway's horizontal and vertical design, phase order, construction timing, and construction needs streamlined the maintenance-of-traffic plan early and helped us identify critical construction constraints. It was essential to anticipate changes to the maintenance-of-traffic plan because different sections would need to be completed at different rates, which meant that delays in one section could impact the progress of other areas. This was especially critical because of certain changes in traffic that were contingent on ocher changes happening first.

Open communication between the designers and contractors helped determine the level of plan modification needed without overworking a simple change. It helped to determine the scope of any changes so char the designers would not corner the contractor with plan revisions; likewise, we worked to ensure that a contractor's request would not require an unanticipated reconstruction or additional temporary work later.

Ac the same time, the ability to adjust the design was critical to the Horseshoe's success, especially when we could combine multiple operations within the same phase to limit lane closures. This proved to be most effective when we were able to conduct bridge work, overhead sign work, and pavement and striping work all in the same location.

Rebecca Fly, A.M.ASCE, a WSP project manager, met with stakeholders early and often to learn and understand the project scope and to facilitate those adjustments. This allowed the WSP team co-deliver high quality drawings and provide effective project management. During the construction phase, engineers fast-tracked production by deploying multiple design teams, all working simultaneously from as many as eight WSP office locations.

Bringing the discipline design leaders, construction field engineers, superintendents, and TxDOT officials into one collaborative group nor only optimized innovations, it also expedited constructability and owner reviews of the design packages because the reviewers were already familiar with the design. The open communication process was further enhanced by increasing the amount of face-to-face interaction and by colocating the PLC construction team and the TxDOT representatives.

One of the key principles of continuous improvement is to listen to the labor force and value its input. The Dallas Horseshoe is a testament to what can be achieved with that thought in mind, as well as the realization that innovative ideas don't come exclusively from the engineers. For instance, we received many great suggestions from the construction crews who were out on the project site and could see where improvements might be possible. In particular, the field personnel were able to visualize ways to reduce utility conflicts and provide ideas for detouring traffic.

As a result, we employed recommendations from the field on numerous occasions. With open lines of communication, field personnel were encouraged co present their observations and thoughts co the designers. If it was an idea chat had merit, it would be incorporated into the plan through a process chat was often completed within two days. This became useful for many of the structural details on the project, such as the retaining walls and stormwater drains.

It's no secret that engineers are often reluctant to use or be involved in design/build projects. However, my experience on this project showed me two important benefits of the design/build approach:

- Improved quality. The designer, contractor, and TxDOT officials worked together throughout the project to ensure that there were no errors or quality issues. Any problems identified along the way were promptly corrected at the design team's expense-which gave us a very strong incentive to provide the highest quality possible.

- Collaboration. The working relationship between the designer, contraccor, and TxDOT officials was outstanding. Everybody pitched in to make improvements, keep the project on schedule, and focus on quality.

WSP's engineers participated in weekly technical working group meetings attended by WSP discipline leads; the contractor, San Antonio-based Raba Kistner Consultants Inc., as the quality firm; and the owner's staff. Those meetings were split into disciplines-roadway, drainage, bridges, retaining walls, and traffic-with the focus on phased construction, facilitating construction progress, and keeping traffic moving. The teamwork was outstanding, and it became a critical component in the success of this project. In particular, our engineers learned a great deal about construction issues that contractors face-issues that engineers, myself included, sometimes overlook. Those considerations.included finding space for construction equipment, providing access for material delivery, and creating safe working spaces for construction crews.

Another focus involved keeping the construction schedule on track, especially in moments of adversity. Throughout the project, the priorities for construction changed frequently, depending on the availability of the craft workers and work areas. But the focus always remained on obtaining the highest efficiency for construction. For instance, the Horseshoe project was constructed during an unusually wet cycle for Dallas-in fact, water reached the banks of the Trinity River three times during the life of the project, which limited the ability to complete bridge foundation work in the floodway. However, the flexibility provided by the design/build contract enabled us to re-prioritize the work to keep the project on schedule.

The Horseshoe is located within one of the oldest sections of Dallas-a constrained area with numerous utilities. As a result, the project required the relocation of nearly 150 major utilities involving the natural gas, fiber-optic communications, electric power transmission, wastewater, and public water systems. Fortunately, TxD0T had, early on, relocated the site's electric transmission lines. But interfacing with the other utilities posed some unusual challenges.

For example, the city of Dallas had numerous wastewater and water lines in the area-some as large as 96 inches in diameter-that WSP tried to avoid relocating as much as possible. We achieved this in the design by following a protect-in-place concept for the wastewater trunk line.

Passing under the Horseshoe project were several large sanitary sewer pipes, some of which directed stormwater from downtown Dallas to the Trinity River. These pipes had been constructed in the 1930s and 1940s and were expected to need replacement due to age. But a detailed inspection and condition assessment program concluded that only a few systems needed immediate replacement and that six protected-in-place, no-touch sanitary sewer lines had decades of remaining service life.

Using a special structural cap design known as a trampoline, new pavements were installed above the sewer lines to straddle these fragile services. The caps consisted of two layers of a geogrid fabric sandwiched within a flexible base material. This system was layered over the sewer lines that cross the I-30 interchange diagonally and parallel the northbound frontage road. This system protected the sewer lines and saved thousands of dollars by obviating the need to replace the lines with new pipes.

In other situations, we did relocate certain utilities, and we constantly had to adjust the design to accommodate utility issues. But we understood that this was part of our scope of work, not a setback. When there was a utility conflict, we were prepared to respond and adjust our design.

Using a vacuum-truck excavation process, our team was able to identify the precise horizontal and vertical locations of the underground utilities, which was a great help in mapping out the utilities to make accurate design adjustments to our original plan. The ability to obtain accurate and complete utility locations also allowed the design team to avoid utility conflicts and minimized the need for redesigns.

The public often has a less-than-favorable view of highway construction projects because of their inconvenience and often lengthy durations. So PLC and WSP worked to turn the design/build delivery method into a way to minimize overall disruption to the traveling public and reduce the intensity and time the public was inconvenienced. One such example involved the bridge design on the eastern side of the project. Because of the tight curves and difficulty of locating bridge bents over and around the main lanes of the Mixmaster, the TxD0T concept plans initially called for the construction of several long bridge spans using steel plate girders. But PLC and WSP reworked the underlying roadway, inserting bents where there were conflicts with utilities. In other cases, the bents were reworked to simplify the traffic control phasing. This, along with other techniquessuch as building decks wider than needed for roadway function-allowed us to convert the steel spans into precast, prestressed concrete girder spans. Concrete spliced girders were designed to comply with the requirement for a minimum of four 250 fr spans across the Trinity River basin between the river's levees.

With no steel fabrication needed, we reduced the girder lead time, which made it possible to open the bridge to traffic sooner than if it had been constructed with steel girders. Furthermore, the maintenance life-cycle costs were reduced, which will have a lasting benefit for TxD0T.

Concrete spliced girders for long-span bridges in North Texas are rare-there had been only two such installations before the Horseshoe project. In part,. that's because such girders required advanced technology, techniques, and equipment to analyze, design, fabricate, and erect properly. But by successfully utilizing these girders on the Horseshoe project, we redefined current engineering thinking, especially for this region.

The Horseshoe project also includes a signature bridge designed by world-renowned architect and engineer Santiago Calatrava, Ph.D., who has offices in New York City and Zurich. Known as the Margaret McDermott Bridge and located on the northwestern part of the Horseshoe project, the twin structure features two distinct, decorative arches that rise 350 ft above the Trinity River. The 1,125 ft long bridge incorporates pedestrian and bicycle lanes on either side of the twin spans, connecting the crossing to the city's growing network of pedestrian trails. {At press time, the pedestrian and bicycle lanes had not yet opened.} Calatrava was under contract to the city of Dallas; WSP was not involved in the design of the Margaret McDermott Bridge. Bur the success of the overall project depended upon a close working relationship with the Calatrava team to make sure our highway design was compatible with the bridge.

The Dallas Horseshoe project has been recognized with awards for its design and overall improvements to transportation in the region. The Design-Build Institute of America selected the project for a 2017 National Award of Merit in Transportation,m and the American Council of Engineering Companies (ACEC) of Texas named the Dallas Horseshoe the winner of the 2018 Engineer Excellence Award gold medal for transportation and was named the Eminent Conceptor awardee, representing the top engineering project in Texas. The project also received the Honor Award at the 2018 ACEC National Engineering Excellence Awards Gala on April 17. These awards reflect the positive feedback we have been hearing from TxDOT and Dallas city officials. In addition to those accolades, we have been getting comments from motorists who benefit from the improved interchange every day.

Nearly every motorist traveling through Dallas uses this interchange, and many people pass through it several times a day. Today those drivers are experiencing significantly faster travel times. Moreover, the Horseshoe not only relieves Dallas traffic congestion, it does so with infrastructure that is both aesthetically pleasing and cost-effective. Personally, to have had the opportunity to be a part of that effort from the beginning, and to see the benefits that it is creating, has been quite rewarding.